Looking for an additional product designer?

DaanID can provide a temporary product designer for your team. Having a flexible product designer can be valuable, whether it's supporting sprints, providing technical expertise, or offering general reinforcement during uncertain times.

Projects often start with a few days per week for several weeks or months. Part-time projects can also evolve into long-term collaborations lasting several years, as long as they are not continuous.

Are you interested? Please get in touch to see if we can be of assistance to each other.

Urban Arrow

In collaboration with the engineers and designers of Urban Arrow, worked on the improvement and innovation of the family cargo bike:

- - Development and improvement of accessories.

- - Optimization of the steering behavior to prevent shimmy effect.

- - Development from initial ideas to series production of specific cargo bike front suspension .

- - Involved in development and prototyping the cargo bike of the future.

Tasks included: Manufacturing parts using milling, forging, bending, injection molding, welding assemblies, technical drawings for production.

Tover

Worked in the design team of Tover on two projectors that playfully challenge people with dementia to communicate. Patients are encouraged to respond to stimuli or engage in play, bringing them one step closer to the world around them.

Tasks included: Building a CAD models, new concept development, detailing sheet metal, prototyping, creating a manual and develop packaging.

Acoustic Inside

The handheld scanner Aurisvue from Acoustic Insight captures real-time images of the middle ear through the eardrum.

With Acoustic Insight, I worked on a first translation from breadboard to product design for the handheld scanner Aurisvue, which creates real-time images of the middle ear through the eardrum. The goal was to further develop the technology and validate the product in a medical environment.

Tasks included: Concept development, CAD modeling, prototyping, assembly, and designing printed and milled parts.

Cassini

Deeply involved in the development of the Cassini Ambient corneatopographer. This medical camera analyzes the cornea, enabling better contact lens fitting or laser treatment. Part of the team from the early prototype stage to the first series production, translating the optical breadboard into a module in a user-friendly product for patients and optometrists. The project was in collaboration with Spark Design and Innovation, Philips Innovation Services and Multin Hittech.

Tasks included: Creating a CAD model and designing parts for milling, injection molding, and vacuum casting. Technical drawings up to the production level.

EasyScan

I have been closely involved in the development of the medical retinal camera EasyScan from the very beginning. This camera captures images of the retina without the need for pupil-dilating drops. The project involved transforming the early optical breadboard prototype into an optical module, resulting in a user-friendly and compact product for both patients and optometrists. The aesthetic design was carried out in collaboration with Spark Design and Innovation.

Tasks included mechanical design, CAD modeling, designing parts for milling, 3D-printing and vacuum casting.

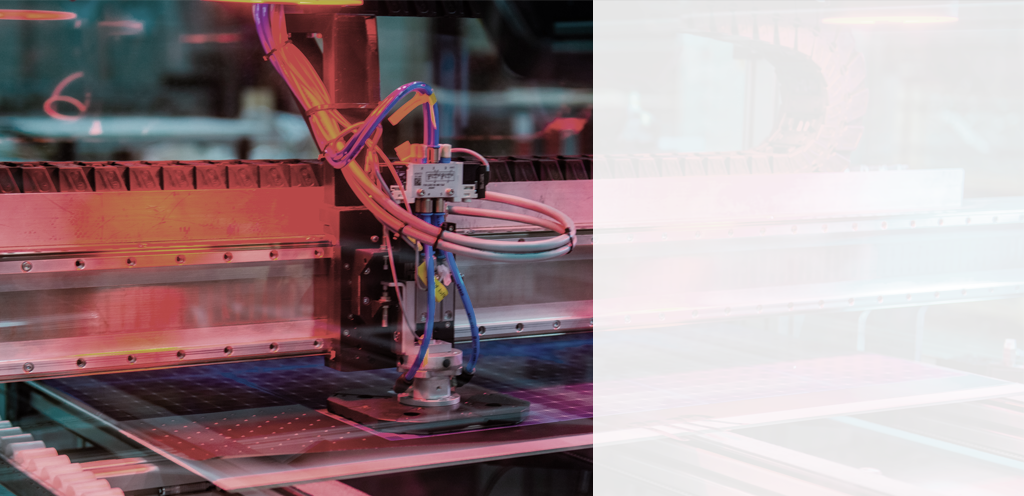

Exasun

Worked together with the engineers of Exasun to develop a set of machines during the startup phase of the company. These machines were used to produce a series of glass-glass solar panels.

- - Pick&Place machine

- - Laminator

- - Stencil Printer

Creating CAD models for both the machines and the solar panels. Developing from scratch till assembling the machines using system profiles and welding assemblies, milled and injection-molded parts.

Spark Design and Innovation

Worked in various multidisciplinary design teams at Spark Design and Innovation on innovative products where specialized mechanical engineering knowledge goes hand in hand with branding and design.

Detailing injection-molded parts for a precision mechanical housing of a medical product. Development of an LED lighting module, casting and sheet metal parts for the housing of a heavy industrial product, and overall setup of CAD models.

Vitestro

Vitestro is developing a machine that can fully automate blood draws from medical patients. Several improvements were made to this machine to enhance reliability, reducing downtime.

Building CAD models, updating TPD, milling, sheet metal, develop and prototype advanced mechanisms, and mechatronics.

Practicum Instructor at TU Delft

Assisting first and second-year students from the Industrial Design Engineering faculty at TU Delft with their initial steps in model building.

The objective is to provide a flying start to a large number of students in a short period and ignite their enthusiasm for model making and designing by practice in general.

We teach students how to create complex or insightful models using standard tools and materials.

Workshop experience, rapid prototyping techniques, laser cutting and 3D printing.

more info: TU Delft - Faculty of Industrial Design Engineering

Roetz-Bikes

At Roetz-Bikes, old bicycles are given a second life. Roetz believes that even new electric bikes should be designed to last a lifetime. With this idea in mind, the Roetz Life e-bike was developed. In the product development team at Roetz, work was done to optimize the series production of the welding assemblies for the front and rear frames.

Building CAD models in Onshape, advanced detailing of stainless steel part forgings. Building functional models of the redesigned rear frame.

more info: Roetz Life